Let’s find out the making process of sawdust briquette charcoal!

Step 1: Collecting sawdust

There is a wide range of raw wooden materials such as wood branches that are crushed into the powder size.

Besides, sawdust is directly collected from a timber factory, chopstick factory or furniture factory.

Step 2: Rotary screening

The materials are screened after the milled materials are put into the rotary drum screen. The wastes are gradually filtered out when passing different meshes of the screen.

Step 3: Drying and removing the metal particles

The crushed particles are conveyed to a dryer by a conveyor belt. In this stage, it can remove excess moisture, the moisture levels are still above the recommended 10-12 percent. Then, the dried material is passed the magnet to remove all the metal particles.

Magnet

Dry machine

Step 4: Sawdust extruding

Then, the material continues to feed the sawdust extruder. Through the control of the mold cone, the material particles are more compact between the compression, and then pressed through the die mold, finally, the sawdust briquettes come out.

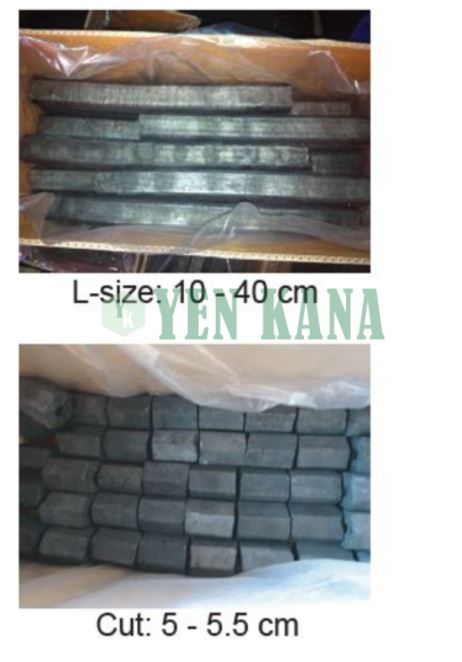

Step 5: Carbonizing

The sawdust briquettes are fired into charcoal. To do this, they are placed in a sealed kiln and ignite them for 5 to 7 days later and after reaching temperatures of up to 700-800 degrees celcius under anaerobic conditions.

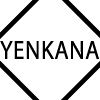

Step 6: Packaging

The workers put bars of sawdust briquette charcoal into the customized carton box with nylon bag.

If you want to buy this amazing product, simply call us on +024.6253.3080 (available in Vietnamese, English, Japanese) or email us on yenkanavn@gmail.com

Yen Kana Company Limited

Head office: 6th Floor, No. 49 Trung Kinh Street,

Trung Hoa Ward, Cau Giay District, Hanoi, Vietnam.

Tel: (+84) 24 629 57 800

Email: yenkanavn@gmail.com